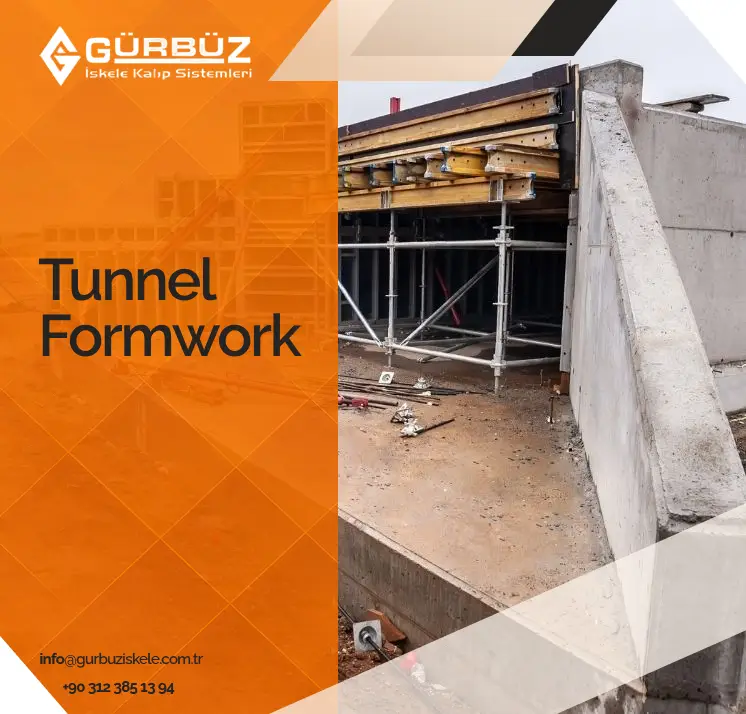

Tunnel formwork is an innovative formwork system widely used in the construction industry to accelerate the building process of reinforced concrete structures. This system allows for the simultaneous construction of walls and slabs, significantly improving efficiency. It is particularly beneficial for large-scale projects such as high-rise buildings, tunnels, and industrial facilities, where speed and accuracy are crucial.

Tunnel formwork also differs from traditional systems by enabling large areas of concrete to be poured in one go, drastically reducing construction time. This method not only speeds up the building schedule but also enhances the quality and durability of the structures. It contributes to cost-effectiveness, as the same formwork can be applied repeatedly, minimizing the need for new materials. As a core element of modern construction technology, tunnel formwork ensures that projects are completed on time while maintaining high safety and structural standards.

Tunnel Formwork Construction

The tunnel form construction process allows for the simultaneous construction of walls and slabs, making it an ideal choice for projects that require repetitive units. The use of tunnel form reduces labor costs and increases the structural integrity of the final product by providing uniformity throughout the build.

One of the key elements in concrete formwork is ensuring that the mold can be reused multiple times without compromising on quality. The tunnel construction method excels in this area by offering durable forms made from steel or aluminum, which can be easily set up and dismantled. The robust nature of the reinforced concrete structures achieved through this technique ensures longevity and high resistance to external forces.

- Tunnel formwork systems are designed for rapid assembly and disassembly.

- The use of tunnel formwork diagram helps engineers visualize and plan the entire construction process.

- Each form is crafted to match the specific dimensions required for the project, ensuring accuracy.

In conclusion, tunnel formwork construction provides a faster, more efficient way to build concrete structures while maintaining the strength and durability of traditional methods. The use of tunnel form and concrete formwork is becoming more prevalent as the construction industry continues to seek methods that balance speed with quality.

A tunnel formwork system is a construction method that allows the simultaneous casting of walls and slabs using large reusable steel or aluminum forms. It is commonly used in the construction of repetitive units like apartment buildings and tunnels, speeding up the process while ensuring structural consistency.

Some disadvantages of tunnel formwork include the high initial cost of formwork materials and the need for specialized labor to assemble and operate the system. Additionally, its application is limited to projects with repetitive design, making it less suitable for more complex or customized constructions.

Tunnel formwork dimensions vary depending on the project, but typical sizes range from 2.4 to 3 meters in width and up to 6 meters in length. The exact size is often customized to meet specific project requirements.

The cycle of a tunnel formwork slab typically takes one to two days, depending on the complexity of the project. This includes the setup of formwork, concrete pouring, curing, and the removal of the forms for the next section.

Tunnel Formwork System

The Tunnel Formwork System is an advanced and efficient construction method that has become a staple in the development of large concrete structures. By allowing both walls and slabs to be poured simultaneously, this system significantly accelerates construction timelines while ensuring structural integrity. The use of concrete tunnel forms provides a reusable and durable solution, allowing for multiple applications without sacrificing quality.

One of the major advantages of the tunnel form system is its versatility in handling various construction types, from residential buildings to tunnels and industrial projects. The form construction technique used in this method streamlines the entire building process, reducing labor costs and minimizing errors. Here are some of the key benefits:

- Steel formwork is highly durable, capable of withstanding multiple cycles of use.

- The system ensures consistent quality across all projects, maintaining high precision.

- Tunnel lining is made smoother and stronger, protecting the structure from external pressures and wear.

Overall, this system is not only efficient but also cost-effective, making it an ideal choice for large-scale construction projects. The robust tunnel lining and durable steel formwork contribute to the longevity and safety of the completed structures, ensuring they meet modern engineering standards.

Gürbüz İskele, realizes the production and sales of tunnel formwork with its long years of experience and mastery. You can contact us for detailed information and applications.